Digitally Manufactured with Natural Precision

Natural Shelters are designed using industry leading 3D CAD software. Once the design is agreed with the client, the design team get to work and 3D computer models are created for all parts. These models are used to:

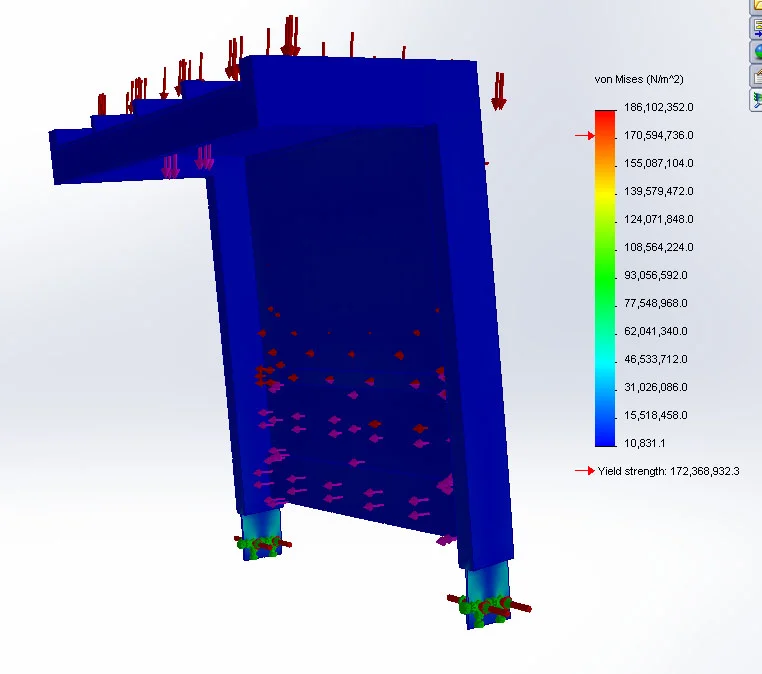

Finite Element Analysis is undertaken using CAD to test snow and wind loads of a cantilever shelter. Results are then reviewed with a structural engineer if required.

- Refine the aesthetics of the design and explore variations

- Model the stress and forces within the structures

- Create bespoke configurations of design variations

- Create complete Bill of Materials (BOM) for accurate costing and stock control

- Create all fabrication drawings for suppliers in their own digital machinery such as high speed CNC wood machining centres, laser and water cutting machines, CNC sheet-metal punching and folding machines.

Once agreed the CAD data is sent directly to the computer controlled machinery to produce shelters that are efficient in their use of materials and function, and built to exacting tolerances of <0.1mm.

The following video shows 3DCAD datafiles driving a multi-tool CNC machine with speed and accuracy. Although the video differs to the CNC machines used to manufacture Natural Shelters it demonstrates the sophisticated level of digital manufacturing in the wood industry.

Our design teams experience in digital manufacturing enables Natural Shelters to be developed with no tooling costs. Our agile design approach also enables bespoke Natural Shelter designs to be realised on demand at very competitive cost.